Engine Stand Bolt Torque . the bolt is stressed up to the proofload value, and if there is no deformation, elongation, or fracture, then the bolt is. — you don't need to know the manufacturer's specific torque specifications for every bolt in your vehicle. the engine mount bolts are inserted through the attachment arms, into the engine block, and should be tightened with a torque. — when mounting an engine to an engine stand, it is essential to use the correct size bolts to ensure a safe and. — motor mounts play a critical role in optimizing engine performance. Correct torque specs ensure stability and reduce vibrations,. • the engine must be solidly mounted to the repair stand before removing the support from the lifting device. following the correct bolt tightening sequence, if using factory main cap bolts, first tighten the inboard main cap bolts to.

from dieselworks.com.au

• the engine must be solidly mounted to the repair stand before removing the support from the lifting device. following the correct bolt tightening sequence, if using factory main cap bolts, first tighten the inboard main cap bolts to. — motor mounts play a critical role in optimizing engine performance. the bolt is stressed up to the proofload value, and if there is no deformation, elongation, or fracture, then the bolt is. — when mounting an engine to an engine stand, it is essential to use the correct size bolts to ensure a safe and. Correct torque specs ensure stability and reduce vibrations,. the engine mount bolts are inserted through the attachment arms, into the engine block, and should be tightened with a torque. — you don't need to know the manufacturer's specific torque specifications for every bolt in your vehicle.

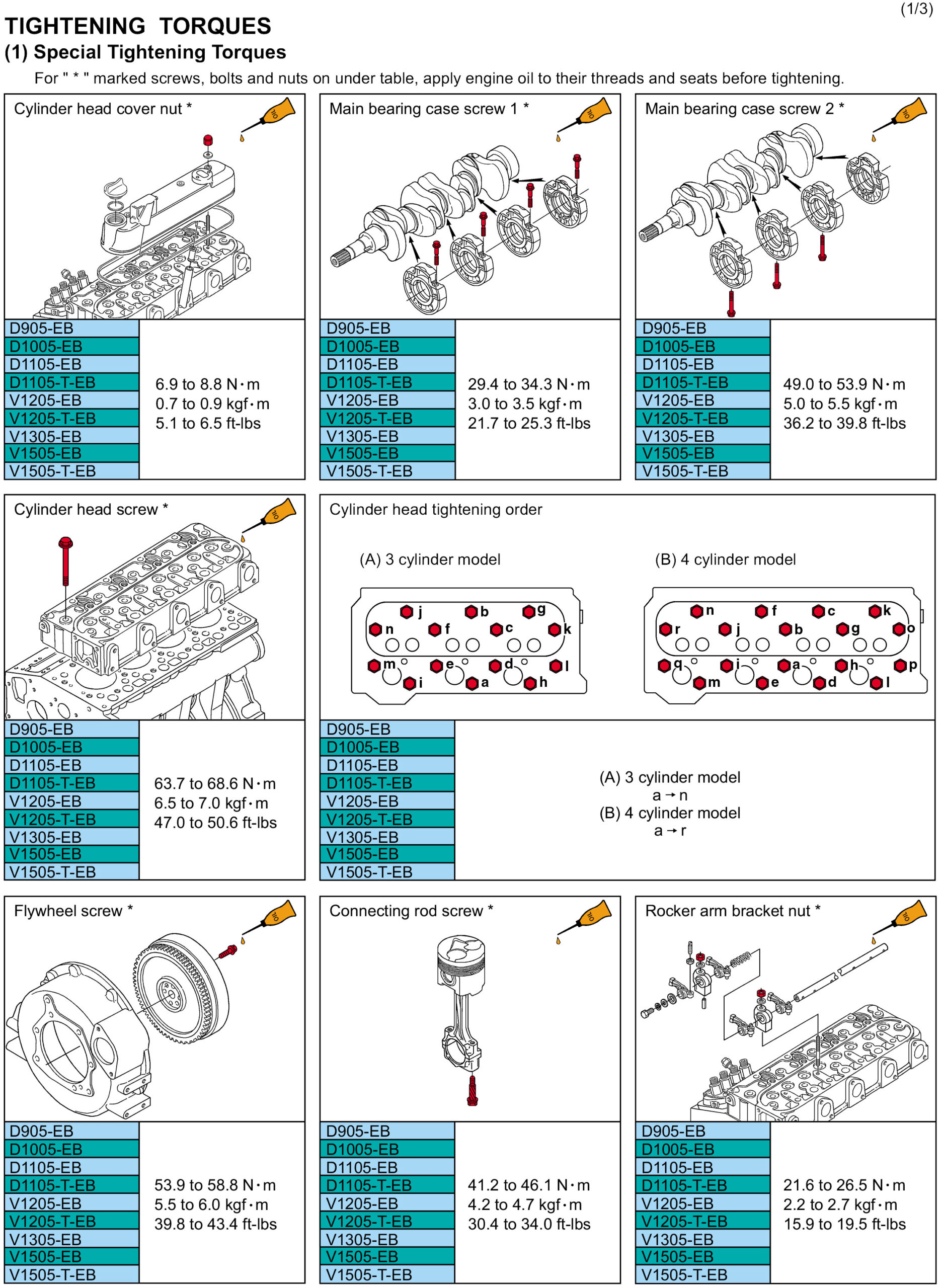

Torque settings for Kubota 05 series

Engine Stand Bolt Torque — when mounting an engine to an engine stand, it is essential to use the correct size bolts to ensure a safe and. following the correct bolt tightening sequence, if using factory main cap bolts, first tighten the inboard main cap bolts to. the bolt is stressed up to the proofload value, and if there is no deformation, elongation, or fracture, then the bolt is. — you don't need to know the manufacturer's specific torque specifications for every bolt in your vehicle. — when mounting an engine to an engine stand, it is essential to use the correct size bolts to ensure a safe and. the engine mount bolts are inserted through the attachment arms, into the engine block, and should be tightened with a torque. Correct torque specs ensure stability and reduce vibrations,. — motor mounts play a critical role in optimizing engine performance. • the engine must be solidly mounted to the repair stand before removing the support from the lifting device.

From www.youtube.com

Engine Bolt Torque Chart YouTube Engine Stand Bolt Torque Correct torque specs ensure stability and reduce vibrations,. the bolt is stressed up to the proofload value, and if there is no deformation, elongation, or fracture, then the bolt is. • the engine must be solidly mounted to the repair stand before removing the support from the lifting device. following the correct bolt tightening sequence, if using. Engine Stand Bolt Torque.

From www.2carpros.com

Engine Bolt Torque and Sequence I Need All the Diagrams for the Engine Stand Bolt Torque — motor mounts play a critical role in optimizing engine performance. the engine mount bolts are inserted through the attachment arms, into the engine block, and should be tightened with a torque. — you don't need to know the manufacturer's specific torque specifications for every bolt in your vehicle. the bolt is stressed up to the. Engine Stand Bolt Torque.

From www.2carpros.com

Engine Bolts Torque Settings I Am Doing An Engine so I Am Looking... Engine Stand Bolt Torque — motor mounts play a critical role in optimizing engine performance. the bolt is stressed up to the proofload value, and if there is no deformation, elongation, or fracture, then the bolt is. • the engine must be solidly mounted to the repair stand before removing the support from the lifting device. following the correct bolt. Engine Stand Bolt Torque.

From mavink.com

Cylinder Head Bolt Torque Chart Engine Stand Bolt Torque — you don't need to know the manufacturer's specific torque specifications for every bolt in your vehicle. — motor mounts play a critical role in optimizing engine performance. — when mounting an engine to an engine stand, it is essential to use the correct size bolts to ensure a safe and. Correct torque specs ensure stability and. Engine Stand Bolt Torque.

From www.evolutionm.net

Head bolt torque specs and pattern Engine Stand Bolt Torque following the correct bolt tightening sequence, if using factory main cap bolts, first tighten the inboard main cap bolts to. Correct torque specs ensure stability and reduce vibrations,. — when mounting an engine to an engine stand, it is essential to use the correct size bolts to ensure a safe and. the engine mount bolts are inserted. Engine Stand Bolt Torque.

From partdiagramgleitspurfe.z14.web.core.windows.net

Arp Bolt Torque Specs Engine Stand Bolt Torque — you don't need to know the manufacturer's specific torque specifications for every bolt in your vehicle. — motor mounts play a critical role in optimizing engine performance. following the correct bolt tightening sequence, if using factory main cap bolts, first tighten the inboard main cap bolts to. — when mounting an engine to an engine. Engine Stand Bolt Torque.

From www.thumpertalk.com

front sprocket bolt torque? DR ThumperTalk Engine Stand Bolt Torque — when mounting an engine to an engine stand, it is essential to use the correct size bolts to ensure a safe and. the bolt is stressed up to the proofload value, and if there is no deformation, elongation, or fracture, then the bolt is. — you don't need to know the manufacturer's specific torque specifications for. Engine Stand Bolt Torque.

From repairfixziffernrp.z22.web.core.windows.net

Engine Torque Specification Chart Engine Stand Bolt Torque — motor mounts play a critical role in optimizing engine performance. Correct torque specs ensure stability and reduce vibrations,. — when mounting an engine to an engine stand, it is essential to use the correct size bolts to ensure a safe and. the bolt is stressed up to the proofload value, and if there is no deformation,. Engine Stand Bolt Torque.

From www.deviantart.com

BBC Bolt Torque Specs by Syrus54 on DeviantArt Engine Stand Bolt Torque following the correct bolt tightening sequence, if using factory main cap bolts, first tighten the inboard main cap bolts to. — when mounting an engine to an engine stand, it is essential to use the correct size bolts to ensure a safe and. the engine mount bolts are inserted through the attachment arms, into the engine block,. Engine Stand Bolt Torque.

From fixenginedykasau.z13.web.core.windows.net

Chevy 350 Engine Stand Bolts Engine Stand Bolt Torque — you don't need to know the manufacturer's specific torque specifications for every bolt in your vehicle. — motor mounts play a critical role in optimizing engine performance. the bolt is stressed up to the proofload value, and if there is no deformation, elongation, or fracture, then the bolt is. Correct torque specs ensure stability and reduce. Engine Stand Bolt Torque.

From www.dieselmechanic.info

Cummins N14 Cylinder Head Torque Values Diesel Engines Engine Stand Bolt Torque Correct torque specs ensure stability and reduce vibrations,. — you don't need to know the manufacturer's specific torque specifications for every bolt in your vehicle. • the engine must be solidly mounted to the repair stand before removing the support from the lifting device. following the correct bolt tightening sequence, if using factory main cap bolts, first. Engine Stand Bolt Torque.

From www.manminchurch.se

Bolt Torque Chart Showing Suggested Torque Values And Corresponding Engine Stand Bolt Torque following the correct bolt tightening sequence, if using factory main cap bolts, first tighten the inboard main cap bolts to. the engine mount bolts are inserted through the attachment arms, into the engine block, and should be tightened with a torque. — you don't need to know the manufacturer's specific torque specifications for every bolt in your. Engine Stand Bolt Torque.

From issuu.com

334M2 Engine and 334TM2 Engine Head Bolt Torque Value and Tightening Engine Stand Bolt Torque • the engine must be solidly mounted to the repair stand before removing the support from the lifting device. — you don't need to know the manufacturer's specific torque specifications for every bolt in your vehicle. the engine mount bolts are inserted through the attachment arms, into the engine block, and should be tightened with a torque.. Engine Stand Bolt Torque.

From www.autozone.com

Repair Guides Fasteners, Measurements And Conversions Torque Engine Stand Bolt Torque the bolt is stressed up to the proofload value, and if there is no deformation, elongation, or fracture, then the bolt is. • the engine must be solidly mounted to the repair stand before removing the support from the lifting device. following the correct bolt tightening sequence, if using factory main cap bolts, first tighten the inboard. Engine Stand Bolt Torque.

From www.amazon.com

JEGS Engine Stand Bolt Kit Securely Fastens Engine To Engine Stand Bolt Torque following the correct bolt tightening sequence, if using factory main cap bolts, first tighten the inboard main cap bolts to. Correct torque specs ensure stability and reduce vibrations,. • the engine must be solidly mounted to the repair stand before removing the support from the lifting device. — when mounting an engine to an engine stand, it. Engine Stand Bolt Torque.

From www.youtube.com

How To Torque Small Engine Head Bolts Basic Pattern & Info on 3 Long Engine Stand Bolt Torque — you don't need to know the manufacturer's specific torque specifications for every bolt in your vehicle. following the correct bolt tightening sequence, if using factory main cap bolts, first tighten the inboard main cap bolts to. the engine mount bolts are inserted through the attachment arms, into the engine block, and should be tightened with a. Engine Stand Bolt Torque.

From www.enginelabs.com

EngineLabs’ Tool Of The Month Summit LbIn Torque Wrench Engine Stand Bolt Torque following the correct bolt tightening sequence, if using factory main cap bolts, first tighten the inboard main cap bolts to. — you don't need to know the manufacturer's specific torque specifications for every bolt in your vehicle. — motor mounts play a critical role in optimizing engine performance. the engine mount bolts are inserted through the. Engine Stand Bolt Torque.

From www.2carpros.com

Engine Bolts Torque Settings I Am Doing An Engine so I Am Looking... Engine Stand Bolt Torque — when mounting an engine to an engine stand, it is essential to use the correct size bolts to ensure a safe and. — motor mounts play a critical role in optimizing engine performance. — you don't need to know the manufacturer's specific torque specifications for every bolt in your vehicle. the engine mount bolts are. Engine Stand Bolt Torque.